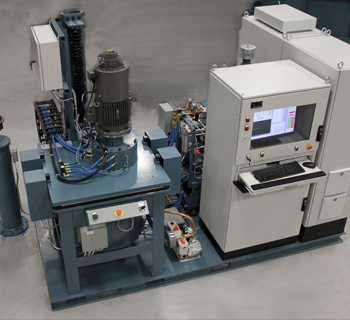

BSi engineers its drive systems to provide ultra-high speed shaft power under precise control. The key advantage of the test facilities designed and manufactured by BSi is the BSi Drive System.

CAPABILITIES

Spin Test Services

Barbour Stockwell, Inc’s in-house spin test facilities incorporate the company’s F.A.S.T. (Full Authority Spin Testing) control system.

Learn More About Spin Test ServicesDrive Systems

The ability of Barbour Stockwell, Inc’s drive systems to provide ultra-high rotational speeds with precise speed control is the company’s key advantage in powering spin tests or driving the components in other test rigs.

Learn More About Drive SystemsSpin Test Facilities

BSi provides the world’s manufacturers of high speed machinery, everything from medical centrifuges to jet engines, with the reliable, precisely controlled, shaft power to put their own equipment to the test.

Learn More About Spin Test FacilitiesOther Test Rigs

BSi engineers draw have the vast experience to provide reliable drives and rigs to meet the most demanding requirements under the most extreme conditions.

Learn More About Other Test RigsBarbour Stockwell, Inc.

Our engineers draw on vast experience to provide reliable drives and test rigs for testing rotating components under the most extreme conditions.

AS9100D CertifiedPORTFOLIO

Industries

-

Aerospace

Aircraft engine manufacturers employ BSi equipment to meet Federal Aviation Administration (FAA) and Joint Aviation Requirements (JAR) to qualify new rotor designs. Not only that, but from the R&D performed to evaluate new materials and designs to pre-spinning production rotors as part of the manufacturing process, BSi equipment is on the job.

-

Automotive

For many years Barbour Stockwell has supplied the ultra high speed spin rigs needed for testing automotive turbochargers. Often overspeed tests are part of the production process; driving rough machined impellers to yield prior to final machining. A more recent development has been the employment of the company’s rigs to perform overspeed, burst and low cycle fatigue testing of Electric Vehicle motor rotors.

-

Power Generation

Barbour Stockwell has provided spin test facilities for processing gas turbine rotors by performing overspeed tests at cryogenic and elevated temperatures. Frequently the rotors are driven past the point where the bores yield. BSi designs and manufactures the complex tooling required to maintain concentricity notwithstanding the extreme plastic strains.

-

Oil & Gas

BSi provides the equipment or test services for turbomachinery manufacturers to meet the overspeed test requirements per American Petroleum Institute Standard 617 for Centrifugal Compressors for General Refinery Service.

-

Abrasives

BSi spin rigs are employed by manufacturers of grinding wheels to perform the overspeed tests specified by ANSI Standard B7.1. Burst testing of samples from a production lot is also used for quality assurance as well as in the qualification of new products.